Supplier MDS Validation Services

Home / Expertise / IMDS Services / Supplier MDS Validation Services

MDS Validation

The Supplier Material Data Sheet (MDS) is a report received from suppliers at all levels of the supply chain for their products. The flow of the supply chain will work in tiers such as Tier-n → Tier-n-1 → …… Tier-1 → OEM. The original equipment manufacturers (OEM) cannot manufacture all the products themselves. Somehow, they will have to rely on other small manufacturers to produce the various parts used in the final product. This is the point where the OEM supplier comes into play and the MDS documentation as well.

Whenever the organization supplies products for an automotive application, the MDS report needs to be submitted to the International Material Data System (IMDS). It is not relevant to what is the function and complexity of the products, from small screws to engine assemblies.

Importance of Supplier MDS Reporting

- Ensure that the products are in compliant to guidelines as per REACH, ELV and

GADSL - Helps suppliers follow original equipment manufacturers’ compliance requirements

- Prevent supply chain or material compliance risks associated with conducting

business in the European Union.

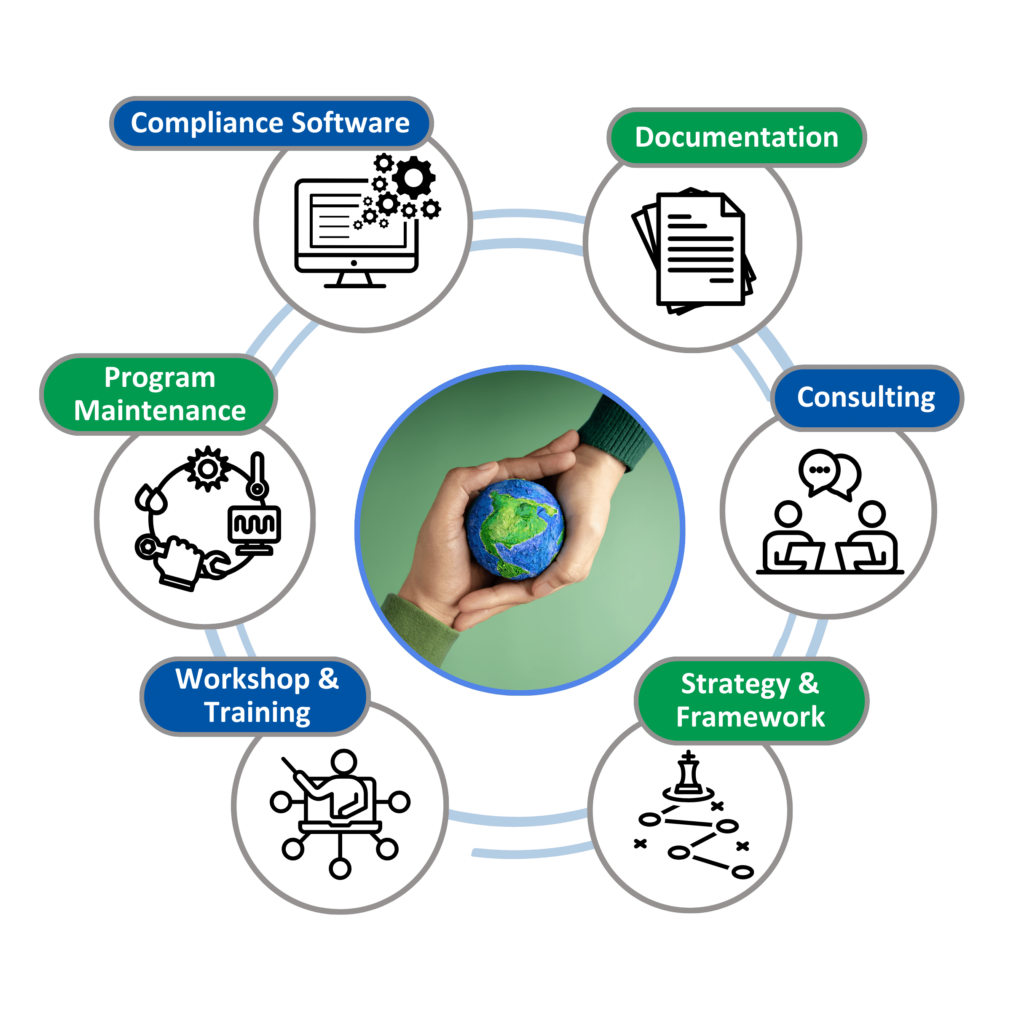

Our Supplier MDS Validation Services include

- Multilingual Supplier Engagement to gather MDS

- Create MDS on behalf of suppliers

- Supplier MDS validation to verify the report structure as per IMDS guidelines

- Implement a cloud-based platform to validate MDS reports

- Ensure that the IMDS report includes compliance data as per the ELV directive

- Identify and track hazardous substances from all parts / materials

- Provide training on IMDS platform usage and MDS reporting

How cumbersome is preparing a Supplier MDS?

There are two cases – collecting supplier MDS at the bottom of the supply chain and validation of MDS before reporting.

- Collecting the MDS report itself is a quite challenging job, especially at the bottom of the supply chain like Tier-3, Tier-4, Tier-5 suppliers. In this part of the supply chain, many of the supplied parts/materials will be raw materials and even the suppliers don’t get a chance to know about the final application.

- Lack of MDS knowledge and requirements of IMDS. Most of these suppliers will not have dedicated teams to generate reports as per IMDS guidelines, and they are unaware of customer reporting practices.

At the top of the supply chain, the MDS collected will consist of a large volume of information in a lengthy structure; validating that report is a time-consuming process, also requiring IMDS expertise to find any gaps as per reporting guidelines.

At ComplianceXL, we provide end-to-end solution for Supplier MDS management such as supplier engagement, platform implementation, training, MDS creation and validation services. Dedicated IMDS specialists will conduct training sessions for procurement stakeholders and end-customers on MDS reporting requirements. Alongside, we provide on- demand consultation to suppliers and OEM on MDS reporting needs.